Plastic Packaging Industry Pioneers

At CoolSeal USA, our mission is to be the foremost extruder and fabricator of plastic corrugated in North America, Our customers and their specific product requirements are our number one priority.

Originally developed by our European partners in Grimsby, UK to revolutionize the seafood industry, CoolSeal USA is now dominating new markets here in the US due to our unique packaging characteristics and versatility. Utilizing state-of-art technology, our CoolSeal boxes and sheet goods are 100% sustainable and 100% recyclable.

The Sealed Edge Technology that we utilize in our Seafood Cold Chain Packaging means its waterproof, hygienic and certified for direct food contact. Our packaging stands out from the competition for being lightweight, durable and robust. Our leakproof designs can withstand the volume of liquid and moisture from the seafood, keeping the product fresh and protected for longer periods of time.

Our products are all manufactured in the USA.

-

More responsive, more flexible, & offering value added services to our customers is our #1 priority.

We are 1 of 8 plastic corrugated extrusion companies in North America. We are not only a manufacturer / extruder, but also a fabricator, much like an integrated company in the paper corrugated industry.

100 years of experience

CoolSeal is one of only 8 plastic corrugated extruders in North America. Not only do we extrude the plastic we also bring over 100 years of experience in the fabrication of plastic corrugated. We differentiate ourselves by being more responsive, more flexible and offering value added services unlike any other North American extruder all while designing cost effective solutions.

What makes us industry leaders

Eco Friendly

Polypropylene is made up purely of carbon and hydrogen and is manufactured without any dangerous emissions, therefore, has zero effect on the environment.

100% Dirt & Dust Free

Our patented sealed edge system can be applied to the packaging by sealing all the open flutes, which makes it imperishable to dirt and dust, easier to clean and reuse.

Custom Size

All of our boxes and packaging can be designed specifically to your needs, so whether space saving is your objective or keeping seafood in the cold chain fresher for longer we can create a packaging solution suitable to you.

Patented Technology

Using our own unique tooling we seal the fluted edges of our packaging, this creates a strong barrier which becomes imperishable to dirt, dust, water and oils.

Faster Cool Down

CoolSeal boxes are tested and proven to cool down products 12 hours faster than traditional polystyrene boxes.

FSA Approved

CoolSeal packaging and our warehouse and factory have been approved by the Food Standards Agency for being suitable for use within the food sectors.

Superior Insulation

Tried, tested and measured, all CoolSeal packaging has far superior insulation properties than our competitors when in a complete cold chain meaning your product arrives safe and fresh.

100% Recyclable

Every component of our packaging; the plastic, glues and inks are 100% recyclable.

100% Waterproof

Perfect for the chilled foods, frozen foods and seafood sectors our packaging will withstand the elements and will trap all moisture and ice melt securely inside the packaging. This is particularly valuable when transporting goods by air freight.

100% Natural

Polypropylene can be incinerated without any harm to the environment, it gives off only water-vapour and carbon dioxide, which is then converted by photosynthesis.

Lightweight

Our packaging is lightweight meaning it is easier to handle, ship and store making it far more user friendly and can help reduce costs.

Resistant to Breakage

Polypropylene is known for its strength and durability. It is suitable for containing heavy loads while also holding its shape and structure.

Made in the United States

CoolSeal proudly manufactures all of its products in the United States, with a strong focus on quality and sustainability. Our CSA Produce Packaging is carefully crafted to keep food fresh and secure through demanding transit, making it the top choice for growers and distributors. With custom printing and branding services, we create packaging that not only protects but also enhances your brand with high-quality designs. Our environmentally friendly corrugated plastic sheets offer a durable, reusable, and recyclable option for various needs, prioritizing sustainability at every step. Partnering with CoolSeal means supporting American craftsmanship and eco-friendly practices designed to elevate your brand and protect the planet.

Patented technology, unrivaled by anything else on the market

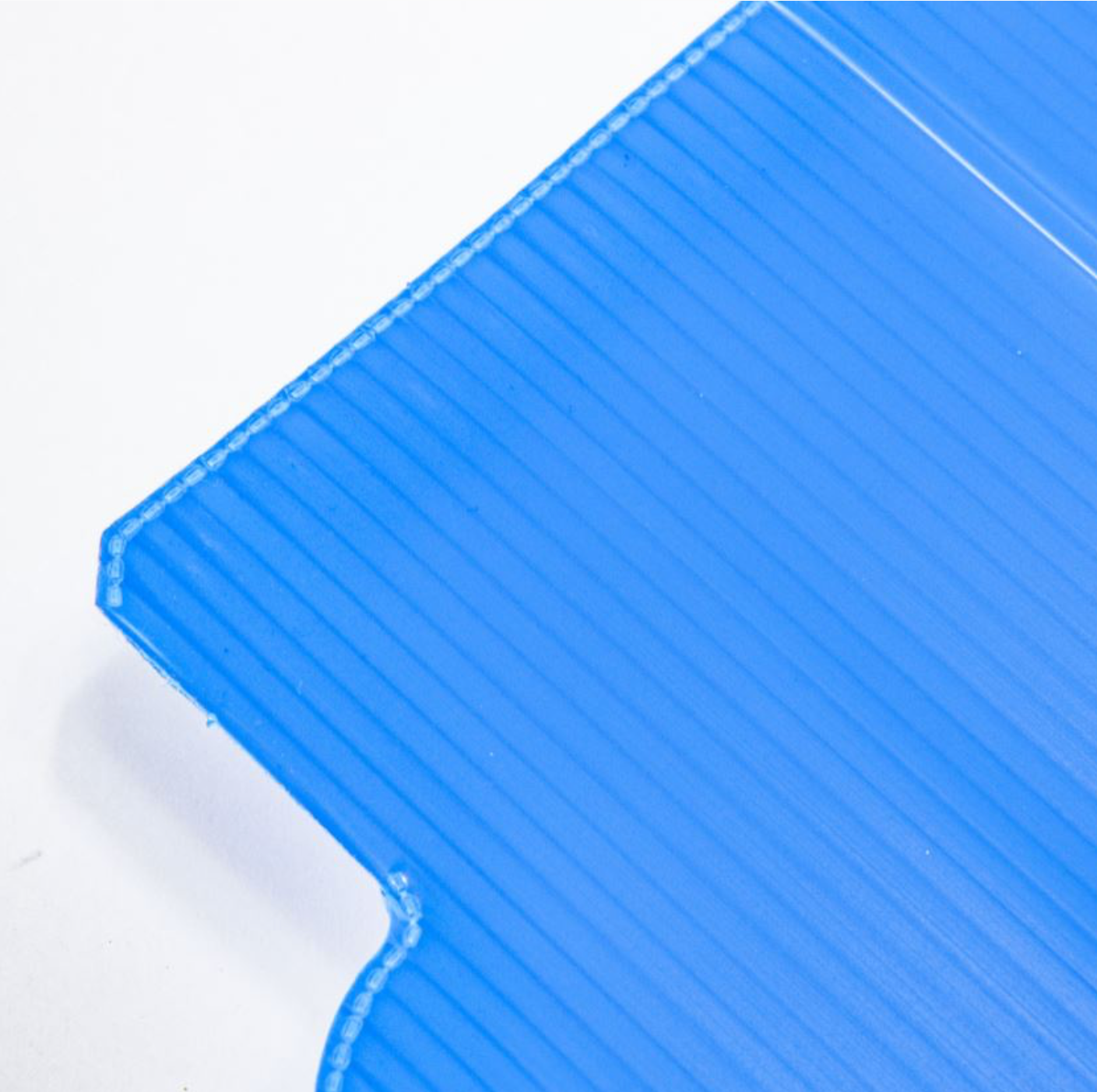

Our sealed edge advancement takes the two open edges; or walls of the polypropylene and seals them together, trapping the air inside. This creates a barrier to the plastic packaging for oil, water, dust, and dirt. In addition to this, the sealed edge insulates our packaging further, provides additional strength and most importantly, stops contamination with the plastic packaging. Fluted PP has a capillary action, where liquid gets sucked into the fluted plastic but having the edges sealed, eliminates contamination within the plastic which is also essential for recycling.

CoolSeal USA's unique sealed edging on all our plastic packaging and other products is what sets it apart from the competition. The sealed edge technology helps provide a strong hygienic pack that is virtually unbreakable. It also makes all of our packaging waterproof, dustproof, dirt proof, strong and insulated.

The extrusion of plastic corrugated is an art form which we have perfected with our Union extrusion line, considered the “Cadillac” of the industry. CoolSeal extrudes Polypropylene sheets from 2mm through 10mm in thickness. While we extrude all Gram weights that have become North American standards, we can work with you to create a custom weight that fits your specific application, differentiating us from any other extruder in North America.

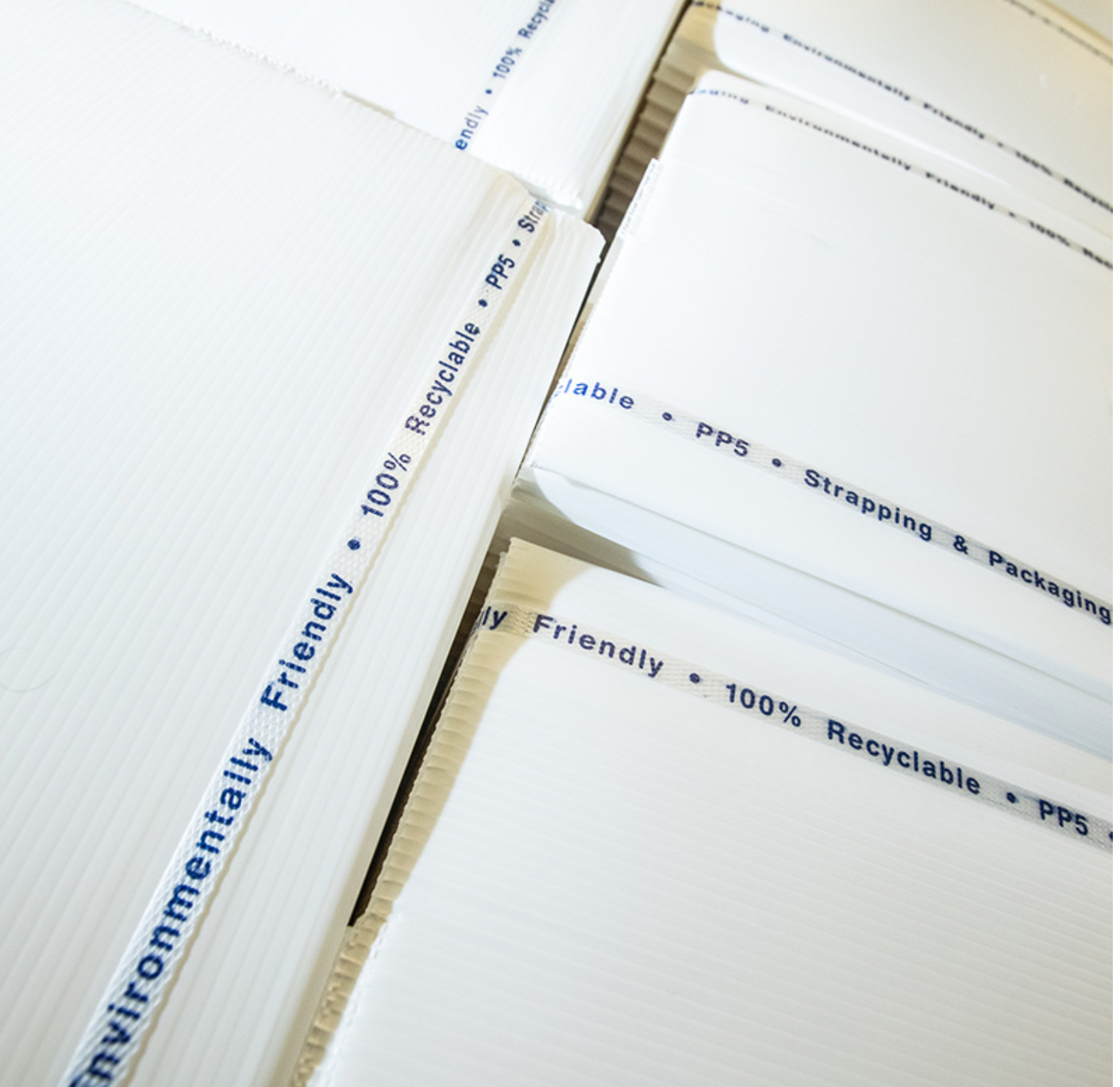

We can prove that 100% of our products can be recycled

CoolSeal doesn’t only claim to produce environmentally friendly and recyclable packaging, we can prove our claims too. Polypropylene, also known as PP5 meets what we call; the circular environment. Meaning the raw product can be shaped, used, recycled and 100% of the original product can be used again for the same application or another. This can be done multiple times in a never-ending cycle, the product is never tired or worn out.

CoolSeal is constantly pushing the boundaries to create products that are diverse and innovative, with state of the art manufacturing techniques and an expert workforce we stay ahead of the competition at all times.